No products in the cart

The art of production

Controlled farms

The uniqueness of Parmigiano Reggiano begins on the farms, where the cows are fed with fodder of exclusive local origin, in a respected and protected environment. The entire process is constantly controlled to maintain the high quality of the raw material, whose characteristics allow Parmigiano Reggiano to be confirmed as an absolutely natural product. The regulations prevent the use of fermented or ensiled fodder, as well as the use of by-products of the food industry and products of animal origin.

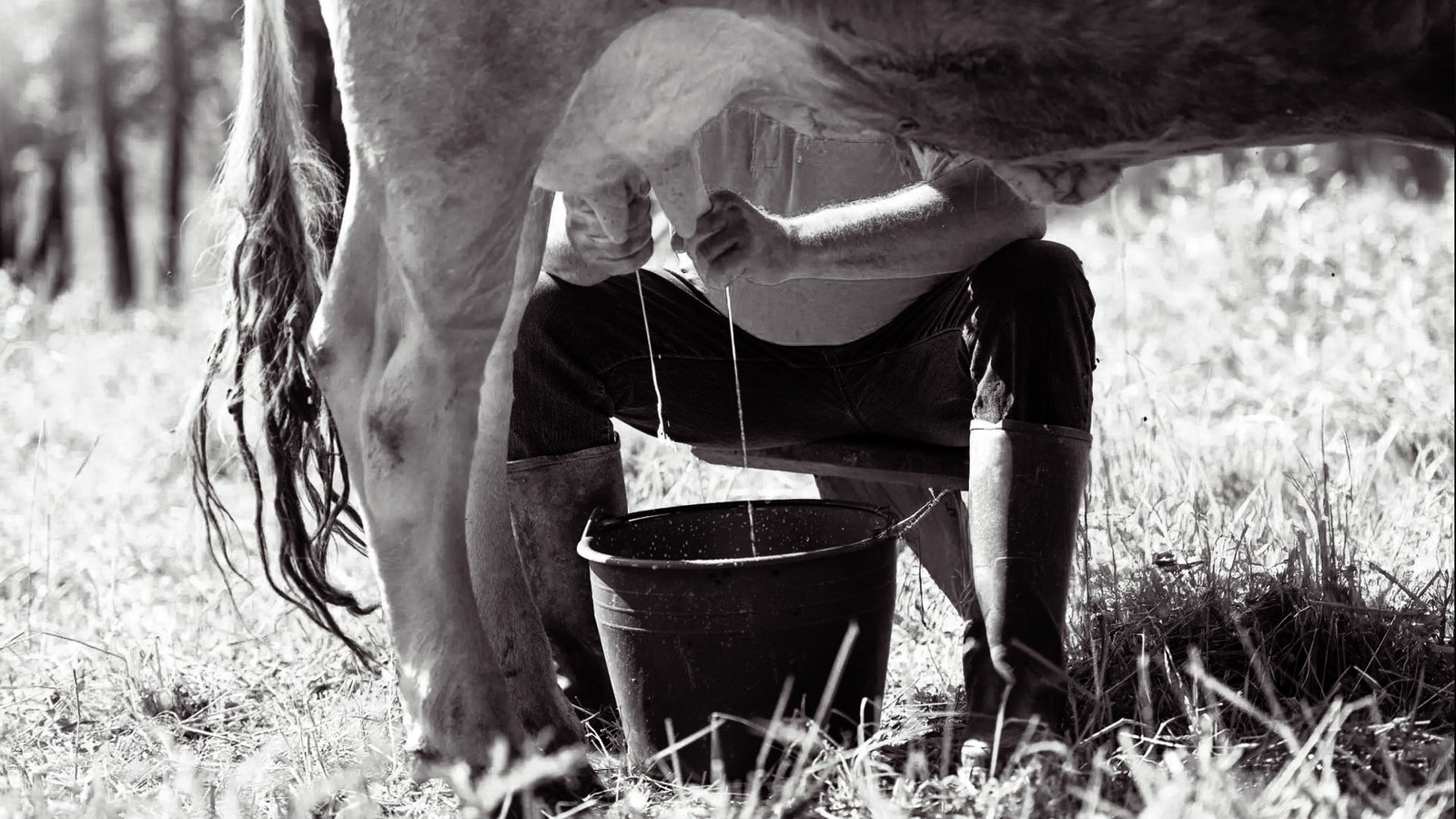

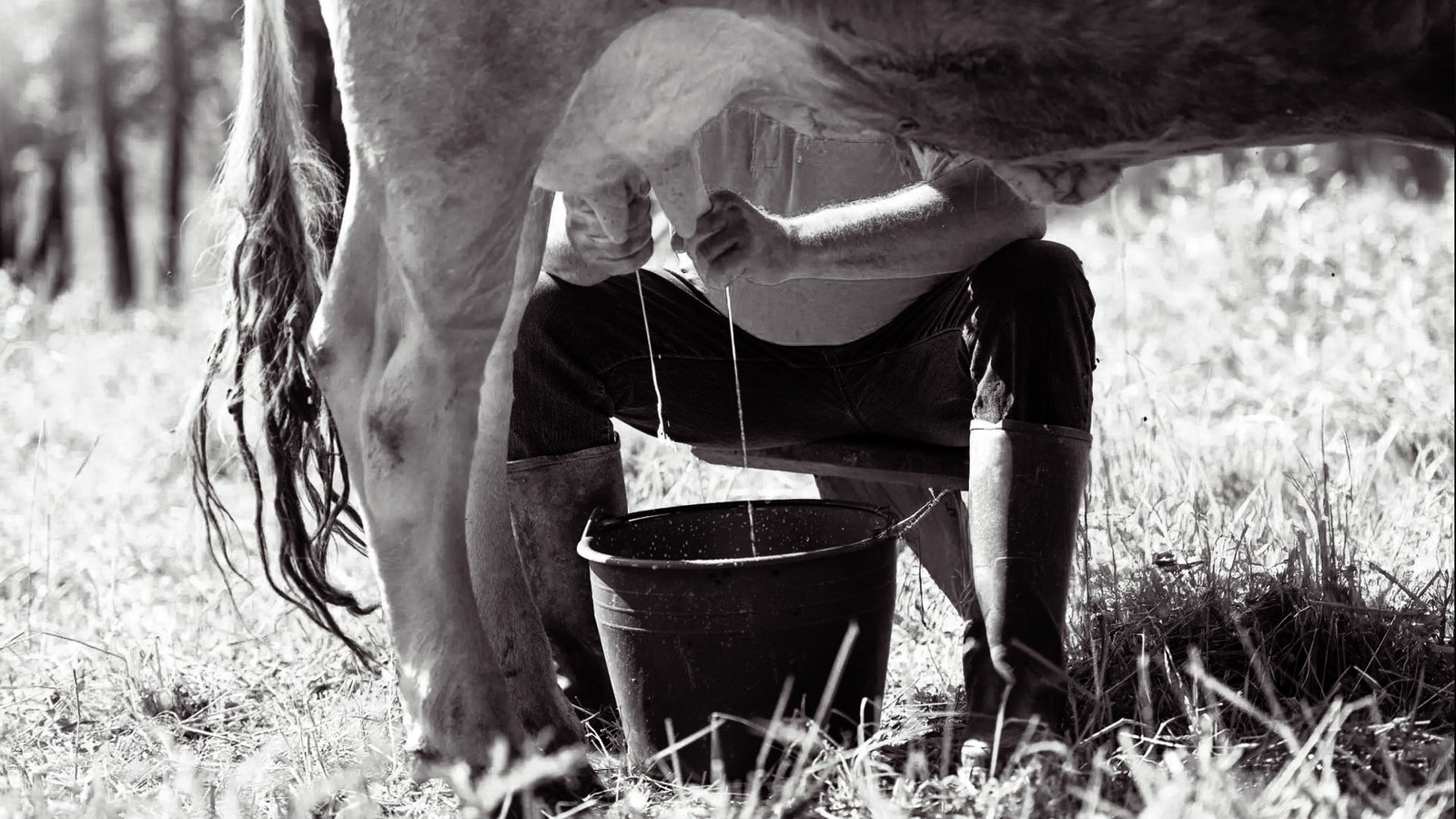

Milking

The milk is collected twice a day. The milk from the evening milking is stored overnight in large tanks, allowing the natural separation of the cream, which is then used for butter and cream production. In the early morning, the skimmed milk from the previous evening is poured into traditional copper cauldrons, shaped like inverted bells, along with the fresh whole milk from the morning milking as soon as it arrives from the farms.

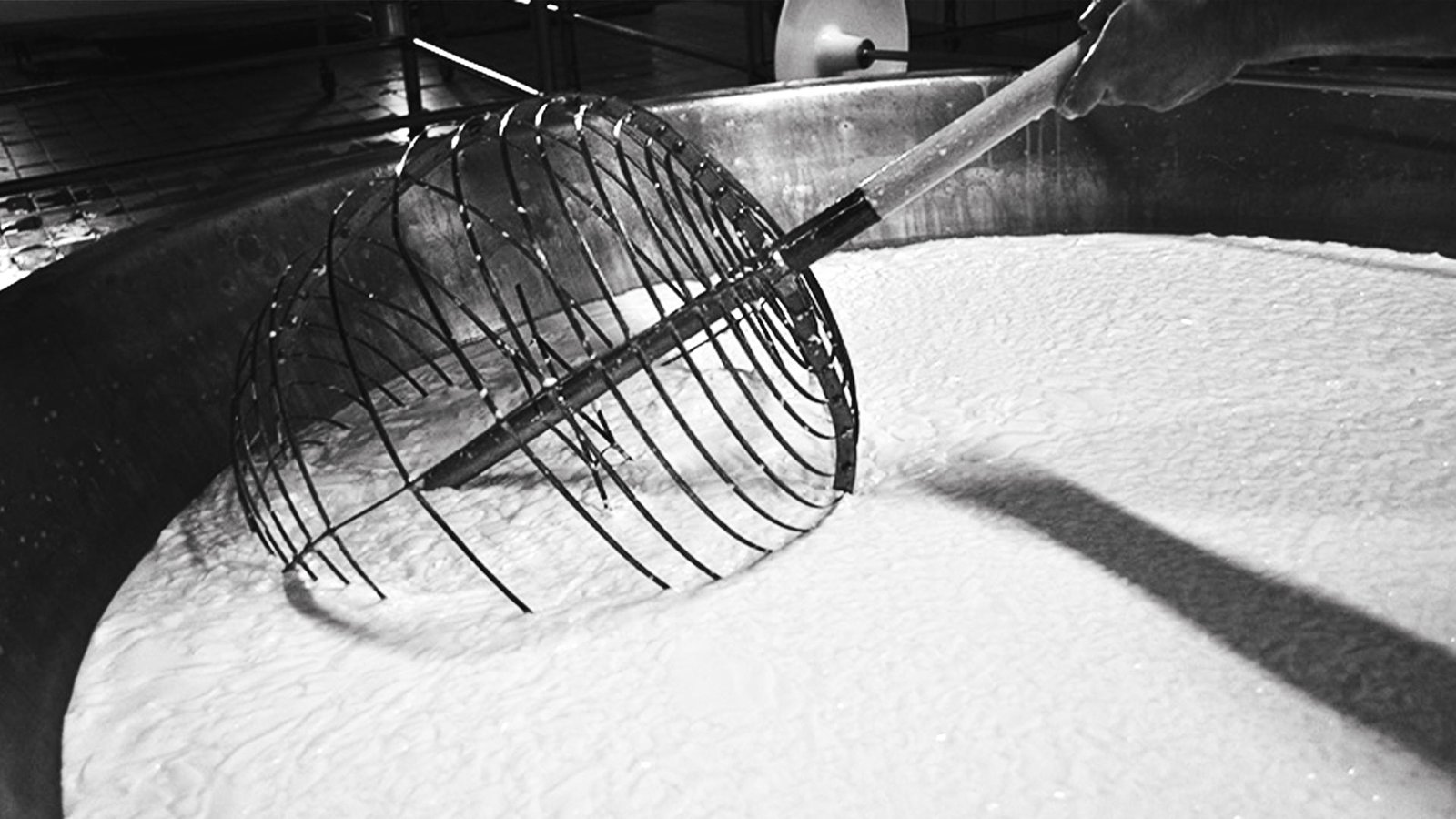

Curd Fragmentation

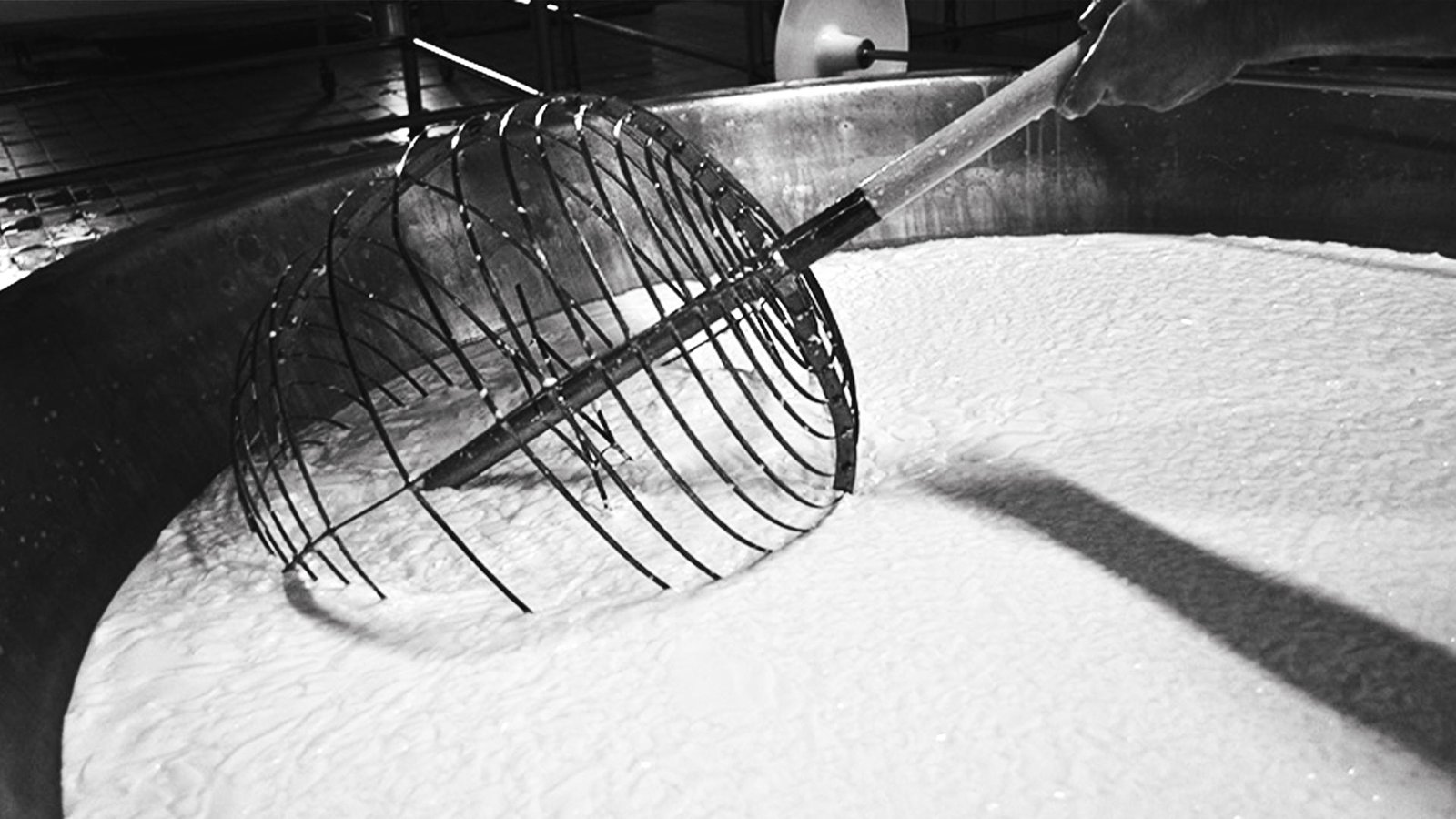

The curd is broken down into tiny granules using an ancient tool called the “spino,” skillfully handled by the cheesemaker. This process is made possible by the addition of natural rennet and natural whey starter, rich in lactic cultures obtained from the previous day’s processing, which promote the natural coagulation of the milk.

The cooking process

This is when the fire comes into play, for a cooking process that reaches 55 degrees Celsius, after which the casein granules precipitate to the bottom of the boiler. After about fifty minutes, the cheesemaker extracts the curd mass, which will give life to two twin forms. To produce one form, 550 liters of milk are used. Cut in half and wrapped in the typical linen cloth, the cheese is placed in a cheese mold that will give it its final shape.

The Unique Identity of Every Wheel

Every cheese wheel comes with its own exclusive identity card! A special casein plate assigns each wheel a unique alphanumeric code, serving as its passport. This system ensures total traceability, allowing its origin to be identified anytime, anywhere! Within hours, a branding band imprints key details: the production date, dairy’s registration number, and the unmistakable dotted inscription. On day two, the wheel is carefully dried, preparing for perfection. This is how every cheese wheel becomes unique, recognizable,

and certified!

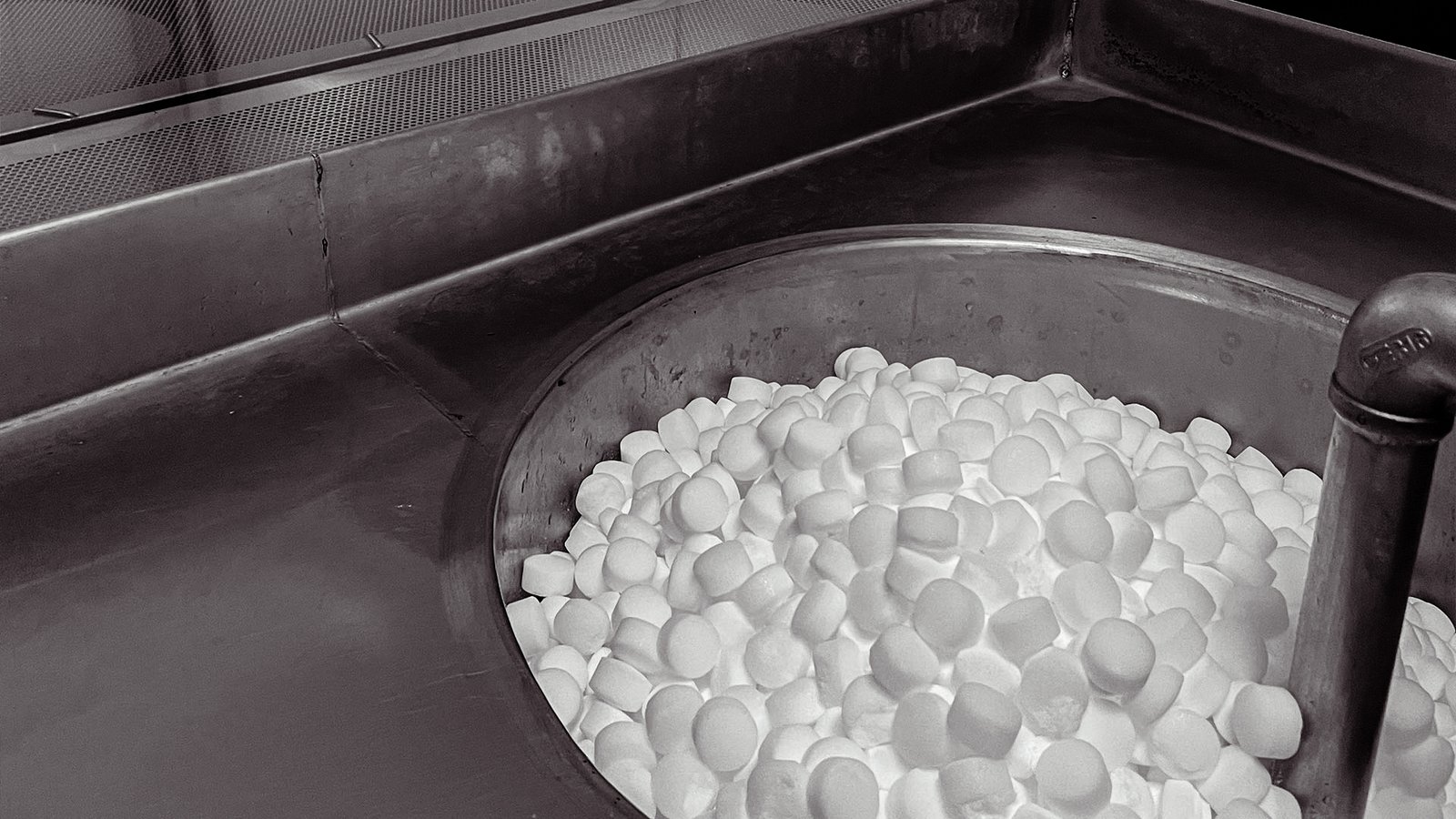

Salting

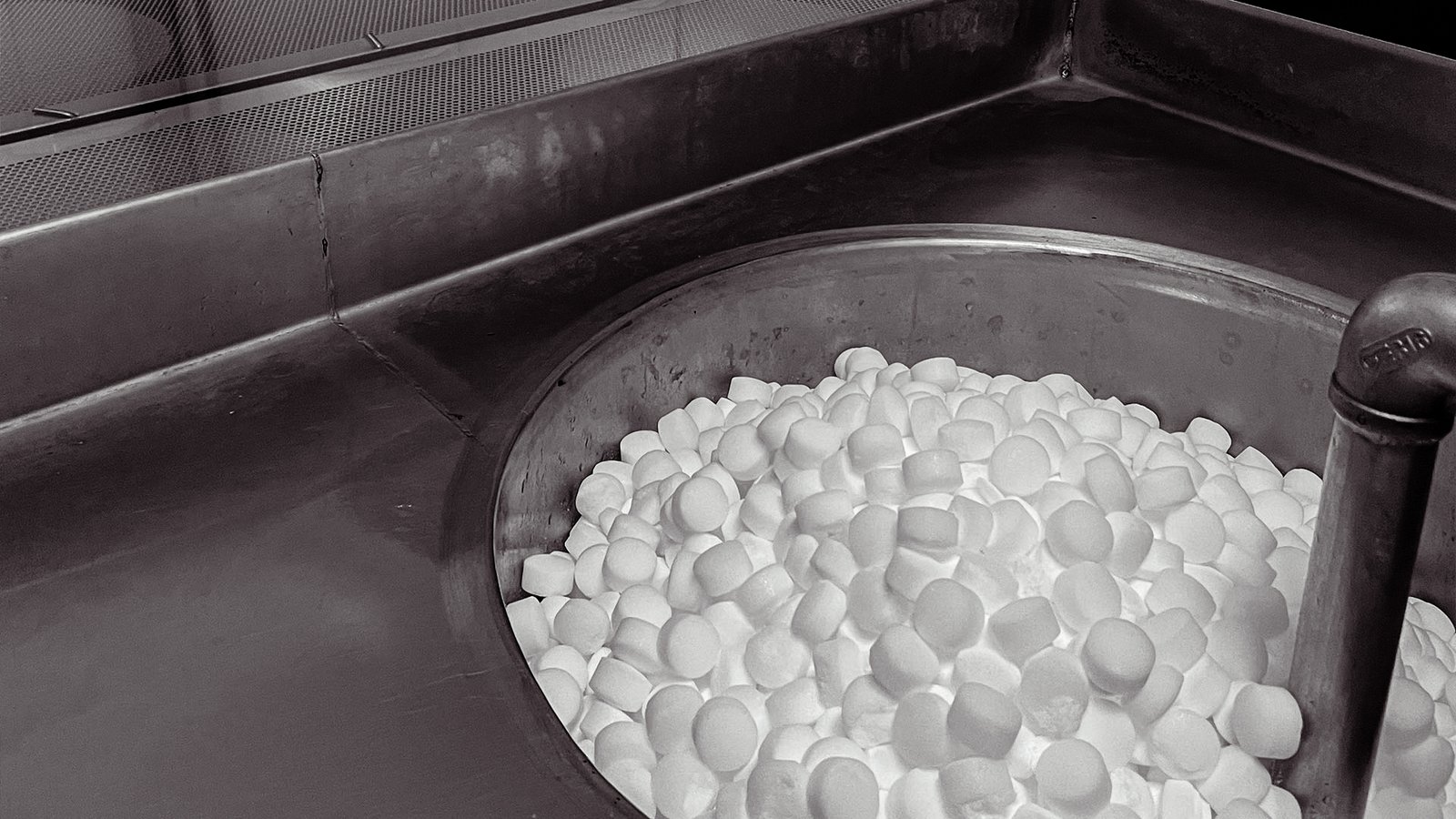

After three days, the cheese wheels are immersed in a saturated solution of water and salt, where the osmosis-based salting takes place! This crucial step completes the production of Parmigiano Reggiano and marks the beginning of its aging journey. From here, transformation begins: day by day, time and care turn

it into a masterpiece of flavour and tradition!

The Sound of Quality

After 12 months, the experts from the Consortium examine each wheel through a process known as “expert testing.” The wheel is tapped with a small hammer, and the trained ear of the tester detects any internal flaws that might affect the quality. The wheels that pass the test are marked with the fire stamp, officially becoming Parmigiano Reggiano. Those that do not meet the DOP (Denominazione di Origine Protetta) requirements have their identification marks and recognition labels removed.

Controlled farms

The uniqueness of Parmigiano Reggiano begins on the farms, where the cows are fed with fodder of exclusive local origin, in a respected and protected environment. The entire process is constantly controlled to maintain the high quality of the raw material, whose characteristics allow Parmigiano Reggiano to be confirmed as an absolutely natural product. The regulations prevent the use of fermented or ensiled fodder, as well as the use of by-products of the food industry and products of animal origin.

Milking

The milk is collected twice a day. The milk from the evening milking is stored overnight in large tanks, allowing the natural separation of the cream, which is then used for butter and cream production. In the early morning, the skimmed evening milk is poured into traditional copper cauldrons with an inverted bell shape, and fresh whole milk from the morning milking is added as soon as it arrives from the farms.

Curd fragmentation

The curd is broken down into tiny granules using an ancient tool called the “spino,” skillfully handled by the cheesemaker. This process is made possible by the addition of natural rennet and natural whey starter, rich in lactic cultures obtained from the previous day’s processing, which promote the natural coagulation of the milk.

The cooking process

This is when the fire comes into play, for a cooking process that reaches 55 degrees Celsius, after which the casein granules precipitate to the bottom of the boiler. After about fifty minutes, the cheesemaker extracts the curd mass, which will give life to two twin forms. To produce one form, 550 liters of milk are used. Cut in half and wrapped in the typical linen cloth, the cheese is placed in a cheese mold that will give it its final shape.

The Unique Identity of Every Wheel

Every cheese wheel comes with its own exclusive identity card! A special casein plate assigns each wheel a unique alphanumeric code, serving as its passport. This system ensures total traceability, allowing its origin to be identified anytime, anywhere! Within hours, a branding band imprints key details: the production date, dairy’s registration number, and the unmistakable dotted inscription. On day two, the wheel is carefully dried, preparing for perfection. This is how every cheese wheel becomes unique, recognizable,

and certified!

Salting

After three days, the cheese wheels are immersed in a saturated solution of water and salt, where the osmosis-based salting takes place! This crucial step completes the production of Parmigiano Reggiano and marks the beginning of its aging journey. From here, transformation begins: day by day, time and care turn it into a masterpiece of flavour and tradition!

The Sound of Quality

After 12 months, the experts from the Consortium examine each wheel through a process known as “expert testing.” The wheel is tapped with a small hammer, and the trained ear of the tester detects any internal flaws that might affect the quality. The wheels that pass the test are branded with the official fire stamp, officially becoming Parmigiano Reggiano. Those that do not meet the PDO requirements have their identification marks and recognition labels removed.